Creosote Deposits

What is Creosote

Creosote is formed from the distillation of tarry, carbon compounds and pyrolysis of organic - plant based materials (firewood). Soot and tar are other common names for creosote and some other "interesting" names include; "creo-soot", creosol, creolsol, black chimney dust. There are many types and ways creosote is formed including as a by-product of burning wood.

Why is Creosote Bad Obstruct Venting - Solid Fuel System PerformanceAs creosote accumulates inside your chimney, it restricts the venting draft of the wood burning appliance and causes poor function.

Risk of Chimney FireCreosote deposits are combustible and when ignited causes a chimney fire. Chimney fires can cause damage to the venting components, your home and in extreme cases injury or death.

Premature DegradationCreosote deposits are very acidic and when left in a wood burning system for prolonged periods of time, it can cause premature system degradation such as corrosion. The best time to sweep a solid fuel burning system is in the Spring after the burning season. This will limit the amount of time the creosote sits in the system and will help prevent premature degradation that may lead to unsuitable conditions.

Air QualityIncomplete combustion of solid fuel emits tiny air particles both inside and outside of your home. The more efficient and cleaner burning your wood burning stove or fireplace is, the less fine particulate matter it will produce. When your home experiences depressurization or when there is inadequate draft in your venting system, spillage of smoke and/or tiny particles and creosote can occur.

How is Creosote FormedWhen you burn a fire, creosote is formed as a by-product of incomplete combustion. The off gases from the smoke condenses as it travels away from the fire - heat source producing carbon, water, combustible deposits on the inside of your chimney. The black residue that builds up is defined as creosote.

|

Canadian Chimney Sweep Service |

Types of Creosote Deposits - Degrees of Creosote

First Degree Creosote

First degree creosote is mostly composed of sooty carbon deposits - "creo-soot". Stage 1 creosote can be easily removed during a chimney sweep service. This type of creosote is a natural by-product of wood burning when there is adequate combustion air, the flue system is warm and is venting properly and wood with a low moisture content is being burned. If you have this type of creosote in your system and not type 2 or 3, you may be operating your wood burning appliance in a suitable manner.

Second Degree Creosote

|

Stage two or second degree creosote is a little thicker than stage 1 and can have shiny, thin flakes. This type of deposit is formed by several factors including inadequate air supply to the fire, cold system temperatures, poor system design and function, lack of maintenance, and wet wood. Stage 2 creosote can generally be removed during a chimney sweep with a power sweep or regular chimney cleaning tools.

Power sweeping is a chimney cleaning tool that utilizes a chimney rod system and cleaning head. When attached to a drill, the chimney cleaning device spins around inside the chimney flue and power sweeps the stage one and two creosote deposits. |

Third Degree Creosote - Glazed Creosote

|

Third degree creosote is also defined as glazed creosote, stage three, or glaze. The black tarry substance is produced when firewood combustion is poor.

Glazed creosote deposits can be attributed to the flue temperatures inside the chimney being cool, inadequate combustion air supply, a poorly designed and/or functioning and wood burning system, wet wood, the use of a gas log lighter, negative air pressure in the building, burning pieces of wood that are too large, burning substances other than dry firewood, unsuitable system conditions, and user error. When third degree glazed creosote ignites, it supplies the chimney fire with lots of energy (longer duration of chimney fire) and produces intense temperatures that may cause damage to your chimney and home. Please see the Glazed Creosote section below for more information. |

Puffed or Honeycomb Creosote

Fluffy puffed creosote that looks like honeycombs is associated with a chimney fire. This type of creosote is produced during an intense heat event such as a chimney fire. Other types of creosote are rapidly expanding forming the puffed, honeycomb like appearance. If you have had a chimney fire, we recommend having the solid fuel burning system inspected within the scope of a level 2 inspection.

Chimney & Wood Burning Appliance Maintenance

When to Clean your Chimney

When the creosote deposits inside the chimney are 3mm or greater, the chimney should be swept. Under normal conditions, the average solid fuel system will accumulate 3mm of creosote after approximately 50 or 60 burns.

Maintenance - Certified Wood Burning Appliances & Equipment

Certified factory built solid fuel appliances such as a wood burning stove or factory built fireplace require maintenance as outlined by the manufacturer. Many wood burning appliance manufacturers require certain components to be evaluated and serviced on a regular basis (more than the chimney sweeping requirements) and require any unsuitable conditions to be rectified prior to use.

Glazed Creosote

How to Remove Glazed Creosote

Glazed creosote is very difficult to remove as it solidifies and cements itself to the interior venting and wood burning appliance components.

In most cases an aggressive chemical treatment repair is needed to convert the glaze into a stage of creosote that can be removed. Heavy or extreme glazed creosote deposits may require several deglazing treatments or may not be fully removable.

In most cases an aggressive chemical treatment repair is needed to convert the glaze into a stage of creosote that can be removed. Heavy or extreme glazed creosote deposits may require several deglazing treatments or may not be fully removable.

Glazed Creosote Treatment Service

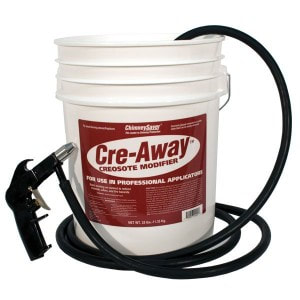

Canadian Chimney offers treatment service to try and deglaze the third degree creosote deposits. We most often use a product called cre-way in combination of an aggressive power sweeping tool and heat (product manufacturers instructions).

We start by scoring the interior surfaces of the chimney and venting components. We then apply the deglazing product with a compressed air spraying tool. After the product has been applied, heat should be applied to the interior of the solid fuel burning system for 7 to 10 days. After the heat application, the system should be swept and evaluated. If deposits remain, these steps should be repeated until the glazed creosote deposits have been removed.

The deglazing product helps neutralise the acidity of the glaze deposits and therefore will help prevent premature degradation of system components (corrosion). The product is also a fire retardant and will reduce the probability of the creosote igniting - chimney fire.

We start by scoring the interior surfaces of the chimney and venting components. We then apply the deglazing product with a compressed air spraying tool. After the product has been applied, heat should be applied to the interior of the solid fuel burning system for 7 to 10 days. After the heat application, the system should be swept and evaluated. If deposits remain, these steps should be repeated until the glazed creosote deposits have been removed.

The deglazing product helps neutralise the acidity of the glaze deposits and therefore will help prevent premature degradation of system components (corrosion). The product is also a fire retardant and will reduce the probability of the creosote igniting - chimney fire.

Creosote Modifying Products

Cre-Awayhttps://chimneysaver.com/product/cre-away-pro-creosote-remover/

Cre-Away Pro is a four-component powder that safely and effectively modifies glazed or third-degree creosote so that it can be more effectively removed by chimney sweeping. First a reactive agent neutralizes the slightly acidic creosote, making it less corrosive to metal components and less flammable. Second, a dehydrator absorbs the oils and moisture contained in some forms of creosote. Third, a combustion inhibitor helps reduce the chance of chimney fires. Finally, a magnesium catalyst helps break down third-degree creosote when the flue is heated by normal use. Apply during the heating season to modify glazed creosote, making it easier to remove. Apply Cre-Away after every cleaning to make any remaining stubborn deposits safer and to neutralize the acidity and odors from the creosote. All chimneys should be inspected and/or cleaned annually by a qualified chimney sweep. Cre-Away Pro contains 50% more magnesium catalyst than regular Cre-Away. The Cre-Away Pro Applicator is a more economical way to apply Cre-Away. So if you find yourself using a lot of Cre-Away, try using the Pro Applicator and buying your Cre-Away in our bulk, 25-lb pail. You’ll save money. Simply insert the steel tube at the end of the hose into the Cre-Away bucket and attach to the gun a small, portable, 1½- to 2-gallon, portable air compressor (sold separately at most home improvement stores). Regulate the air pressure on the compressor to about 20 p.s.i. and blast the Cre-Away Pro up the flue until it is thoroughly coated. |

PCRThis is a very aggressive chemical, and careful safety percautions must be taken when using this product.

https://chimneysaver.com/product/pcr-poultice-creosote-remover/

PCR is a revolutionary product designed to completely remove 3rd degree glazed creosote from flue tiles or stainless steel chimney liners. When PCR is applied, it dissolves the creosote and absorbs it. As it absorbs the creosote and dries, it loses its adhesive properties and falls off the sides of the flue tiles. Any remaining PCR can be easily removed by chimney sweeping. PCR can be applied by brush in areas that are easily accessible or with a specially designed tool that can be pulled up through the chimney by a winch. To remove glazed creosote in smoke chambers, PCR can be applied with SaverSystems’ Smoke Chamber Sprayer. PCR should be used where glazed creosote is present in order to eliminate the dangers of chimney fires. |